Ukraine Turbo Circular Saw Blade for Marble, Granite, Concrete and Stone

Product Description

PRODUCT DETAILS

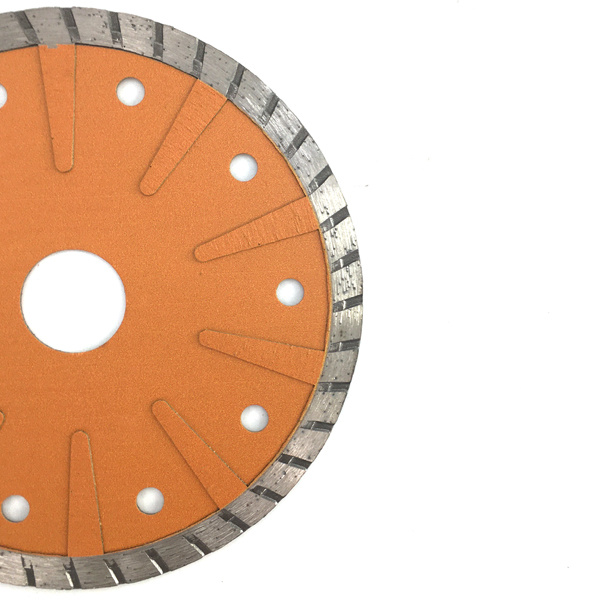

Turbo Circular Saw Blade for Marble, Granite, Concrete and Stone, diamond disk

Brand

Diameter

OEM and ODM

Package

MOQ

Application

General cutting for marble, granite, concrete and stone

ADVANTAGES

Safety: High strength of blade and matrix binding force. Meanwhile, we use special technology in the base, so that the blade can be protected very well.

Sharp: Efficient processing efficiency and stable quality.

Perfection: Optimized formula to more finely differentiate professinal market.

Attentively: Workmanship with the spirit of craftsman and consider the details

Circular saw blades are cutting tools used with electric circular saws, circular saw benches, and table saws to cut wood and wood-based materials. They consist of a central circular blade disc with multiple teeth attached along the edge. As the blade spins at high speed, the teeth slice through the workpiece to make cuts. Choosing the right blade for the job is important for efficient, high-quality cuts.

The material and number of teeth determine a circular saw blade's suitability for different cutting applications. Blades with fewer teeth, like 24 teeth or lower, are good for fast cross-cutting where cut quality is not as critical. Blades with higher tooth counts, like 60 to 100 teeth, produce smoother cuts and are better for finish carpentry work. The material and tooth geometry also depend on workpiece hardness. Carbide-tipped blades are used for hardwood, while high-speed steel blades can cut most softwood and plywood.

For rip cuts and bevels, a blade with teeth specifically designed for cutting along the grain is required. The teeth on these blades have an angle and gullet optimized for shearing wood fibers. Alternate-top bevel and double bevel blade geometries produce clean edges with minimal tearing. Triple chip tooth blades aggressively shear wood for the fastest rip cuts.

APPLICATION

PRODUCT PICTURE

COMPANY CERTIFICATE

DELIVERY

WHY CHOOSE US

We are nearly 20 years professional manufacturer for diamond saw blades, TCT saw blads, abrasive disc, Drill bits and Abrasive Tools.

For our products, we have got CE and MPA certification.

1. Reliable supplier--high quality, good package, resonable and competitve price, fast delivery time.

2. Price-- We are the completely factory, so you can get the lowest possible price.

3. Quality-- From raw material to final products, we take full control of quality inspection.

4. Service-- We offer all-round sales and after-sales service, so the business is so easy.

5. Sample- Samples are available, we can accept both sample order and bulk orders.

6. OEM& ODM-- OEM& ODM orders are welcomed.

7. Response Time-- Any inquiries will be replied within 12 hours.

8. Certificate-- ISO9001, CE, MPA.

FAQ

Q1:what is the advantage of your products?

A1: We are professional manufacturer in this field with lots of years R&D and market research experience,we can provide

competitive price and high quality products for you.

Q2: How is your quality?

A2: We have a very seriously control system(ISO 9001 and SGS product quality control) and 100% QC inspection Before Shipment.

Q3:Payment

A3: TT, L / C, Paypal and Western Union and other payment methods. The payment range comes from different countries and regions.

Q4:What are the way of the transportation?

A4: Depending upon the weight of goods ,we can transfer by express ,air and shipping ,including DHL ,UPS ,TNT and FEDEX

Q5:Can we make OEM or ODM? / Can we put customer brand?

A5: Yes, we can make the OEM and ODM for you if your quantity is large, customer logo, color, shape, package method should be provided by the custom

RICHOICE Catalogue

If you do not have a comprehensive understanding of our products, we have uploaded relevant technical documents for you to download and reference so that you can better understand our product usage and technical parameters

View More

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

+86 511 85891166 , +86 137 0528 3249

NO.66 Runxing Road, Runzhou Private Economy Development Zone, Zhenjiang, China

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans