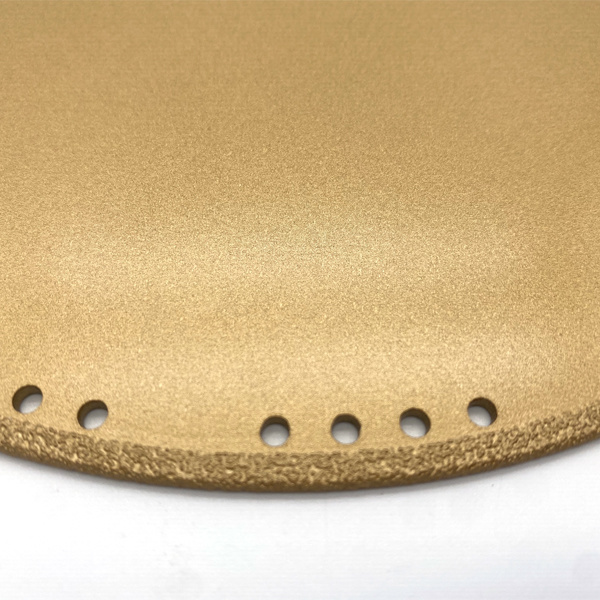

Myanmar Diamond Circular Saw Blade Vacuum Brazed Diamond Cast Iron Cutting steel

Category:

Product Description

Vacuum Brazed Diamond Saw Blade Diamond Tools for Iron

Specification(mm): 100, 105, 115, 125, 180, 230, 300, 350, 400

Hole(mm): 16, 20, 22.23, 25.4, 32, 50

Application: Mainly used for cutting cast iron, ductile iron, reinforced steel, sheet metal, stainless steel, nonferrous metals, etc.

Cutting safety, sharp and durable, it can replace part of electroplated diamond saw blades and common corundum abrasive resin bond cutting disc.

ADVANTAGE

Vacuum brazed saw blades have better sharpness.

Vacuum brazed diamond blades have a wide cutting range.

Vacuum brazed saw blades have a longer life, equal to more than 50 ordinary abrasive discs.

The base of vacuum brazed saw blades is made of high manganese steel and will not be broken.

Tungsten carbide vacuum brazed saw bade for can be used for cutting metal substances in wood.

Vacuum brazed saw blade applies vacuum brazing technology, diamond or tungsten carbide as the raw materials, which can be used for cutting metal, cast iron, wood, stone and etc.

A circular saw blade is a vital cutting tool used in various woodworking, construction, and cutting applications. It features teeth arranged in a circular pattern, allowing for efficient and precise cutting of different materials, including wood, metal, and plastic.

There are several types of circular saw blades, each designed for specific cutting applications. The most common types include ripping blades, cross-cutting blades, combination blades, and specialized blades.

Ripping blades are used for cutting materials with the grain, such as making long cuts in boards or planks. They have large, flat teeth specially designed to remove material quickly.

RICHOICE Catalogue

If you do not have a comprehensive understanding of our products, we have uploaded relevant technical documents for you to download and reference so that you can better understand our product usage and technical parameters

View More

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

+86 511 85891166 , +86 137 0528 3249

NO.66 Runxing Road, Runzhou Private Economy Development Zone, Zhenjiang, China

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans