Iraq HIGH-PERFORMANCE INDUSTRIAL LAMELLAR DISCS FOR INDUSTRIAL USE FLAP DISCS WITH PLASTIC BACKING

Category:

Product Description

High-performance industrial lamellar discs for industrial use

We offer a wide range of flap discs that meet European regulations and the highest safety standards (EN13743). High-quality flap discs ensure even and precise material pick-up. The blades are carefully positioned to achieve a perfectly round blade shape and balance, ensuring precise and comfortable work without vibration or overheating. Reduced diameter discs are also available upon request. They have larger leaves that provide greater softness and flexibility.

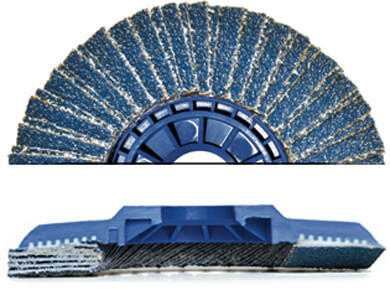

Flap disc with plastic backing

Compared to the fiberglass backing, the plastic gives the blade more rigidity. Available in HT version (thick with narrow leaves), standard version or economy version.

Flap discs with plastic backing are available in zirconia grit, suitable for grinding and finishing virtually all types of steel (also alloyed), and corundum grit, suitable for machining iron and steel.

All flap discs we offer are manufactured and tested in accordance with European standards, maintaining the highest safety standards (EN13743).

Vortex HT

VORTEX HT are the most advanced flap discs on the market. Innovative technical solutions that make it unique:

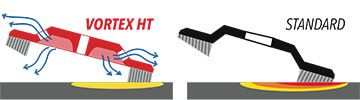

1.Aerodynamic ventilation fins provide airflow and cooling to keep the workpiece cool during machining and reduce the risk of pitting, which is especially important when machining stainless steel. The lower operating temperature also has a positive effect on the service life of the disc.

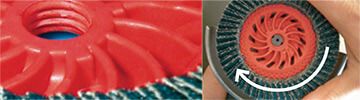

2.Threaded mounting hole for quick, tool-free installation.

3.The leaves in the HT system allow for very high efficiency from the beginning to the end of the blade's life. Distribution of the abrasive compound in the circumferential area of the disc minimizes abrasive waste and premature tool wear.

The special structure of the plastic primer and the arrangement of the leaves allow for high rigidity and density of the abrasive embankment. This blade design allows for accurate and precise processing of a piece of material, even when working at a large angle, the blades remain strong and rigid, which allows accurate and fast work.

RICHOICE Catalogue

If you do not have a comprehensive understanding of our products, we have uploaded relevant technical documents for you to download and reference so that you can better understand our product usage and technical parameters

View More

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

+86 511 85891166 , +86 137 0528 3249

NO.66 Runxing Road, Runzhou Private Economy Development Zone, Zhenjiang, China

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans