Ceuta Richoice Abrasive Cutting Disc for Stone

Category:

Product Description

Material:Cutting disc with ceramic grain

Package type: color box, double blister.

MOQ: 5000pcs

Size: 4”(100mm)-24”(600mm)

Lead time:

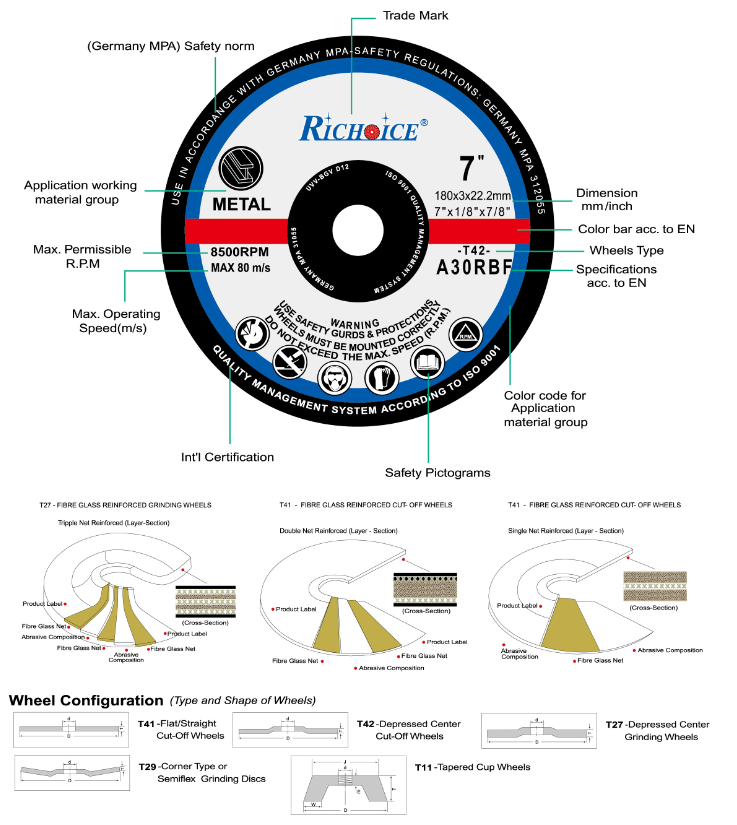

A

24

R

B

F

Primary Grain

Grain Size

Bond Hardness

Bond Type

Reinforcement

A=Aluminum Oxide

C=Silicon Carbide

AC= Aluminum Oxide/ Silicon Carbide combination

Z=Zirconia Aluminium Oxide

ZA= Zirconia Aluminium Oxide/ Aluminium Oxide combination

Coarse/Medium/Fine/Ver y Fine

16/24/30136/60-400

Soft→Medium→Hard

MNO PORST

B=Resin oid

Fibre Glass Nets

Fl=w flay or net

F2=2 layers net

F 2.5=2 and half

layers net

Step 1

The first step is mixing raw material powder, we have a large mixing machine

Step 2

Forming

Step 3

Test after forming: Static balance test

Step 4

Sintered

Step 5

Finished products inspection: Packing inspection & Quality test & Safety test

1.Q: what is the advantage of your products?

A: We are professional manufacturer in this field with lots of years R&D and market research experience, we can provide competitive price and high quality products for you.

2.Q: How is your quality?

A: We have a very seriously control system(ISO9001 and SGS product quality control) and 100% QC inspection before shipment.

3.Q: Payment

A:TT, L / C, Paypal and Western Union and other payment methods. The payment range comes from different countries and regions.

4.Q: What are the way of the transportation?

A: Depending upon the weight of goods ,we can transfer by express ,air and shipping ,including DHL, UPS, TNT and FEDEX.

5.Q:Can you customize the products as per our request?

A: Yes, we accept OEM and ODM. We could make the product suggestion based on your idea and budget.

A new abrasive cutting disc technology has been introduced into the market, promising precise and efficient metal cutting processes. The cutting discs feature a unique and innovative design that allows for quicker material removal, resulting in an overall reduction in production time.

Unlike traditional cutting discs that operate with a tangential cutting motion, this new technology uses smaller abrasive particles to create a more aggressive, surface-based cutting action. This results in smoother, cleaner cuts with minimal heat buildup and reduced burr formation.

The new abrasive cutting discs are suitable for use on various metals, including stainless steel, aluminum, and copper, and are ideal for applications where speed and precision are essential, such as in the automotive and aerospace industries.

In addition to providing excellent cutting performance, the new technology is also environmentally friendly. The discs generate less waste, produce fewer sparks, and result in lower energy consumption, making them a sustainable choice for metal cutting processes.

The introduction of this new abrasive cutting disc technology is set to revolutionize the metal cutting industry, providing faster, more efficient, and environmentally friendly cutting solutions. While the technology is still in the early stages of adoption, it is expected to gain rapid acceptance over the coming years, as industries seek to improve the speed and accuracy of their metal cutting processes while reducing costs.

RICHOICE Catalogue

If you do not have a comprehensive understanding of our products, we have uploaded relevant technical documents for you to download and reference so that you can better understand our product usage and technical parameters

View More

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

+86 511 85891166 , +86 137 0528 3249

NO.66 Runxing Road, Runzhou Private Economy Development Zone, Zhenjiang, China

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans